When a pipe rehab crew installs a CIPP liner, they typically do the job in just a few hours, and then move on to the next project. But that’s not the end of the story. CIPP is designed to last for decades, and the wastewater systems that use it need to be confident in its efficacy. In most cases, installers are required to submit a sample of every liner installed for third-party testing. Only once testing is complete and the results are approved and reported is the job really “done.”

Experts in the CIPP Field

HTS Pipe Consultants is the go-to testing service for many system operators, lining contractors, engineering firms and material suppliers across the U.S. and around the world. The firm has been providing engineering, consulting, materials testing and inspection services to both the public and private sectors since 1979. Among other offerings, it tests liner samples to ensure compliance with design criteria.

HTS is accredited to meet ASTM standards, although it occasionally encounters ISO standards as well. And it has a reputation for quality: It’s one of only two approved providers of Greenbook testing for the City of Los Angeles. While HTS’s role is invisible to many rehab professionals, the work it does is essential to public safety and wastewater management.

Rick Eastwood has been with HTS for over a decade, and he spent twenty years before that as a contractor. He’s seen a lot of change in the relining industry, from the development of new materials and curing methods to the introduction of more efficient and affordable techniques.

But different materials and methods don’t change the role played by the tester. “Materials are designed to meet a standard or a specific design criteria depending on the customer,” he explains. “Once it’s installed and samples are sent to HTS, we test the material in accordance with the appropriate ASTM method. The results will indicate if the samples meet the design criteria.”

Reliable Testing Methods

Testing measures vary depending on materials used in the construction of the liner and the design requirements of the jobsite. Many different parameters go into specifying a CIPP liner, but key factors include depth, water levels and loads. A deeper look into liner design may examine operating pressures and temperatures, potential impact on sensitive environments, and pipe diameter.

“Then there’s the strength of the liner itself,” says Eastwood. “CIPP liners are supposed to last 50 years, known as the design life, and testing can help you confirm this.”

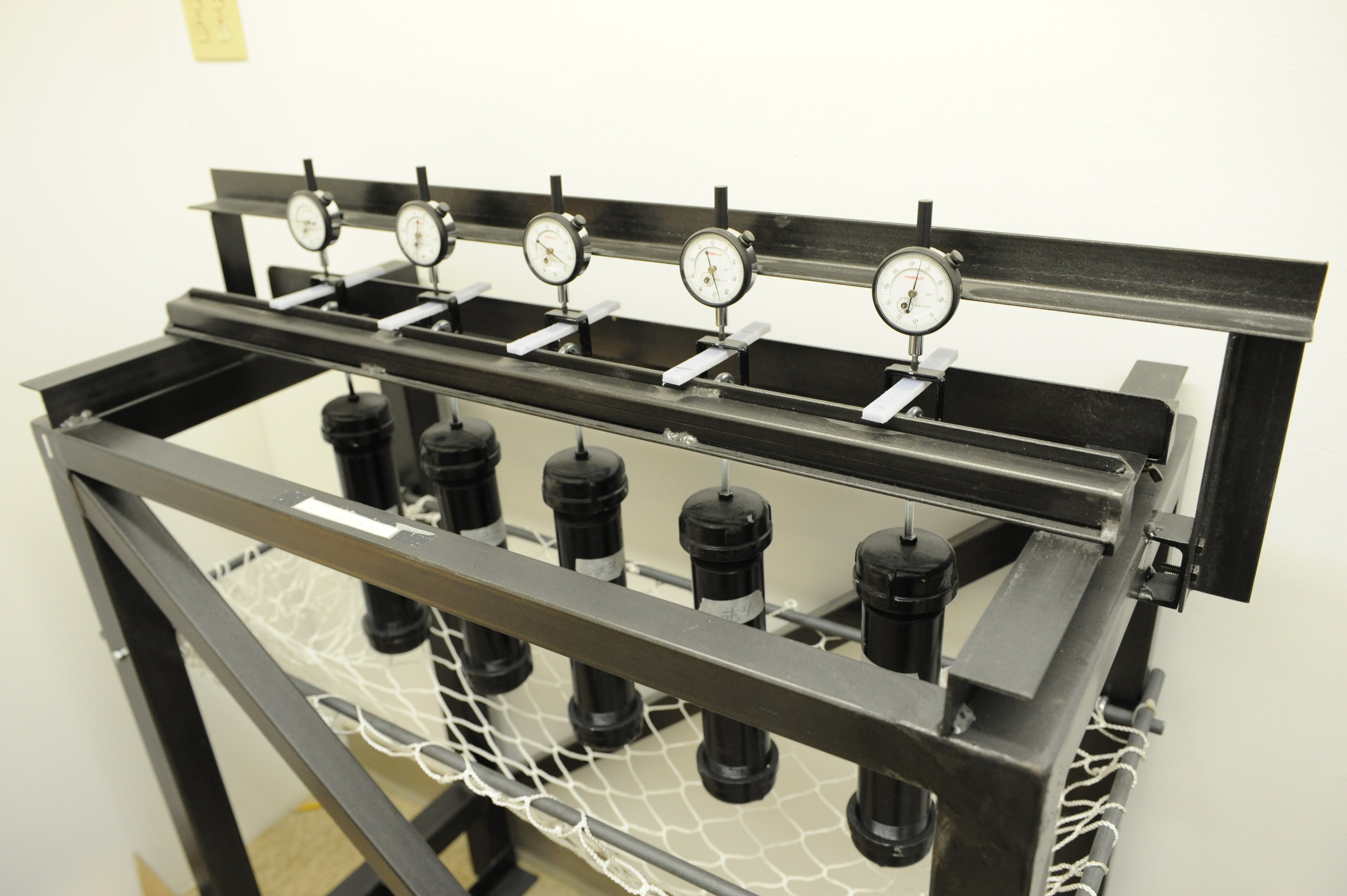

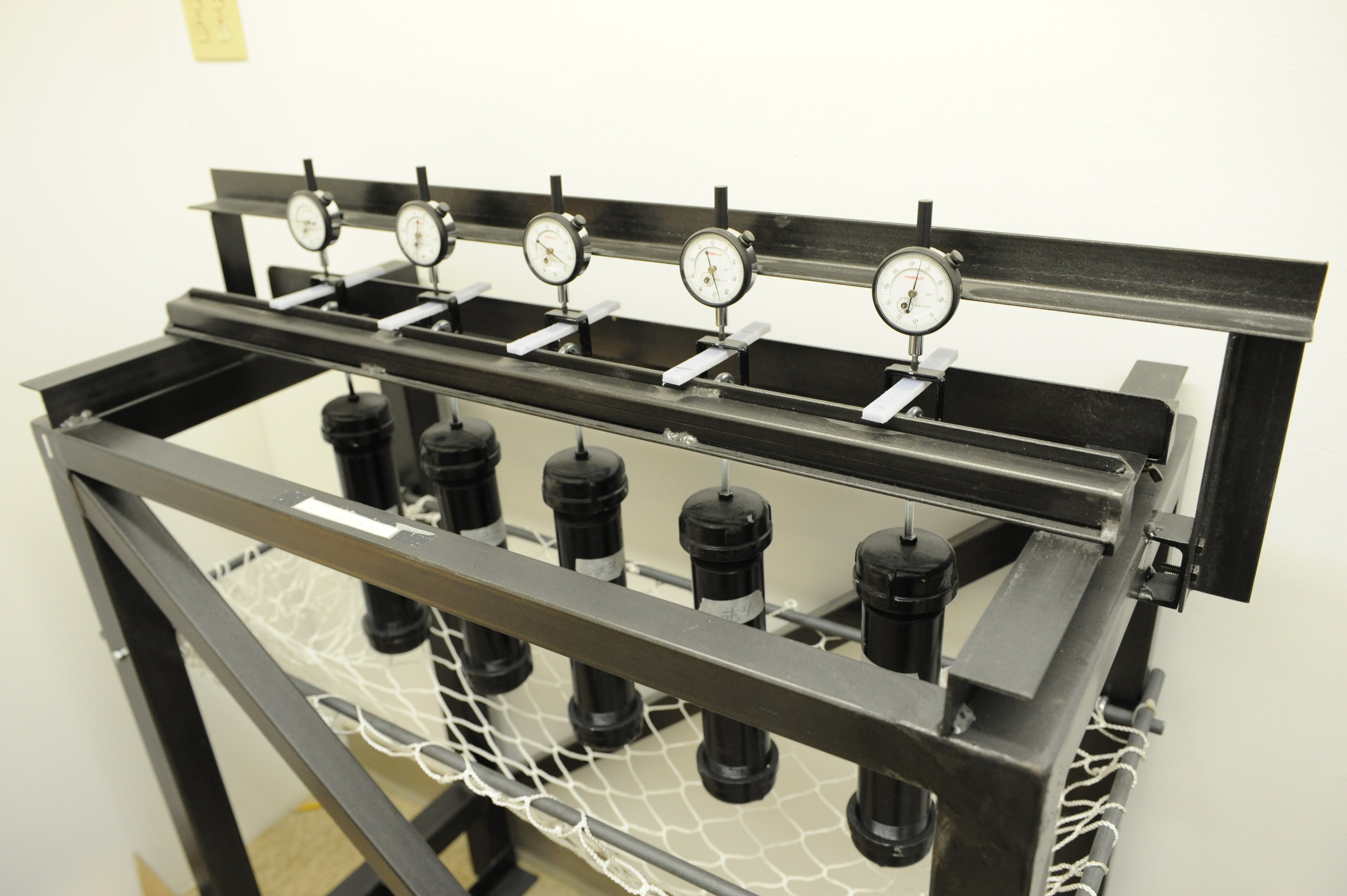

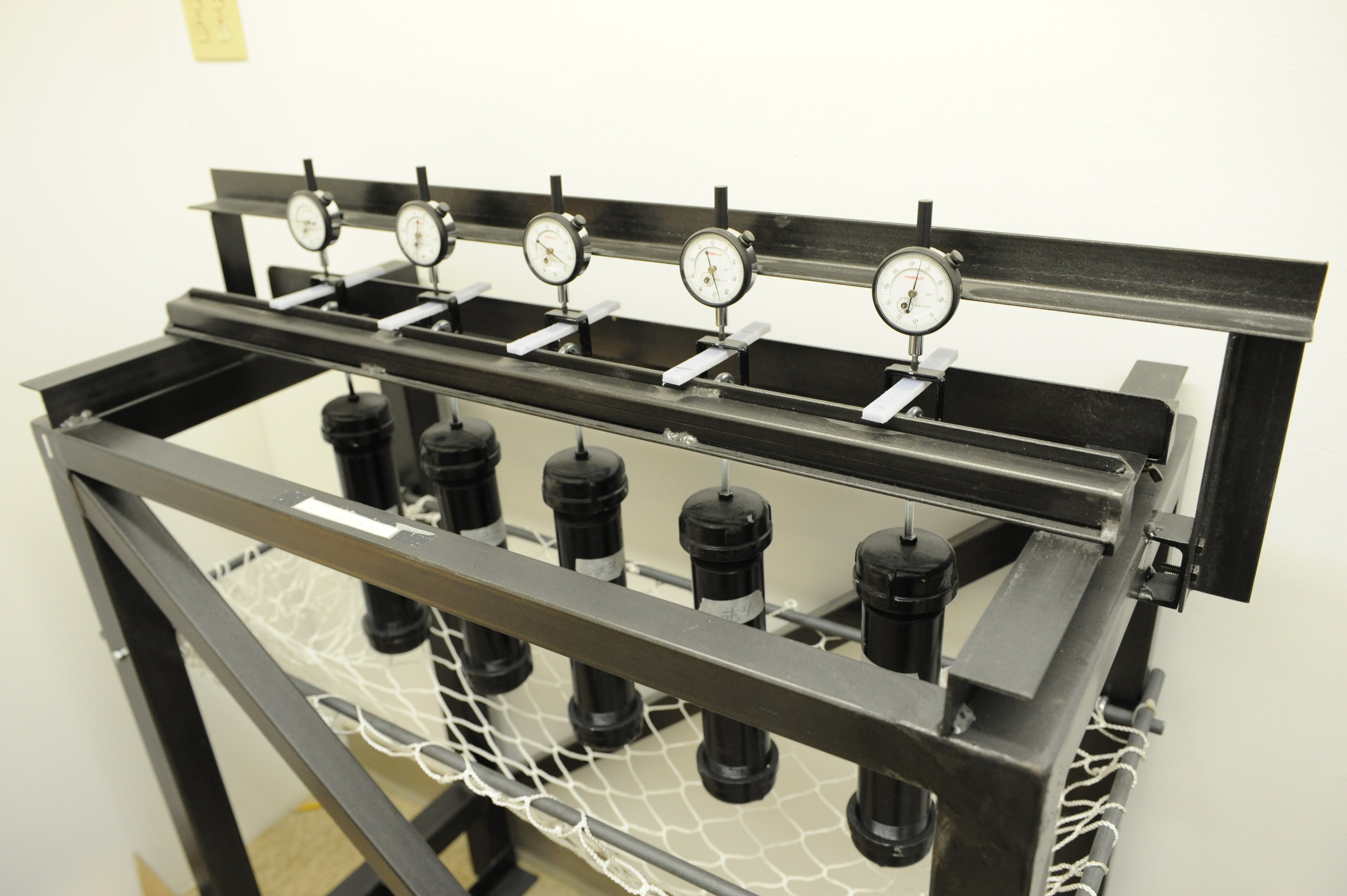

"The standard way to measure design life is with an ASTM D2990 Flexural Creep test. In this test, five specimens are placed under a calculated stress load for 10,000 hours—about 13 and a half months. We record the deflection during this time; then we extrapolate from this data to determine the strength retention of the material at 50 years—typically around 50% of the initial strength. This is why many standards and design programs indicate that the long-term flexural modulus is 50% of the initial short-term value.” It’s also the value installers input in liner design when calculating liner thickness.

Common CIPP Tests

Samples may also be subjected to a variety of other tests and standards:

ASTM D790: This test produces the flexural modulus of elasticity (Flexural Modulus), and is performed in accordance with the requirements listed in ASTM F1216 (for felt liners) or ASTM F2019 (for UV-cured fiberglass liners). It directly ties to ASTM D2990 data for a product. For example, if a product is designed based on the initial flexural modulus from the ASTM D2990 test, the results of the ASTM D790 test must meet or exceed this value. If this value is not met, installers may face pay deductions or worse. “There is a large difference in the methods based on the material,” says Eastwood, “so I suggest confirming what is required in your contract.”

ASTM D638: For tensile tests like this one, specimens are cut in the shape of a dogbone, put in a grip and pulled apart. The resulting data can help the pipe’s operator know the tensile strength of the liner.

Sample Thickness: Liners must meet the thickness indicated in the design. For felt liners, the tester can take simple measurements of the full thickness (ASTM D2122) or measure the full thickness and deduct the coating thickness (ASTM D5813), since coating is a non-structural component of the liner. UV-cured fiberglass liners must be measured in accordance with ASTM F2019, which differs significantly from ASTM F1216. ASTM F2019 requires 30 measurements to determine the “Full Thickness,” and then places each of the samples under a microscope to measure and deduct the non-structural layers (film, coatings and neat resin) in the sample to determine the “Composite Thickness."

Chemical Tests: Various chemical tests can be performed according to ASTM standards, depending on an individual project’s requirements.

How Do Liners Fail?

How Do Liners Fail?

Nearly all the CIPP liners that complete testing pass. But not every sample gets that far. “If I can bend it in my hand, I know it’s not going to pass,” says Eastwood.

Over the years, he’s found a pattern in flawed samples. “After you review the failure, which I like to call CIPP SVU, you will find mistakes are often the result of shortcuts taken. These materials and processes are tried and true. Generally, it’s not the material—it’s the installation.”

“Any product, no matter how good it is, is only as good as the people installing it that day. During install, a number of things can go wrong,” he says. “You lose head pressure, lose your heater, you get lift.”

“Sometimes it’s a good thing though. People need a reminder not to cut corners. You just hope those instances don’t cost too much.”

That’s why testing exists, after all.

The use of light-based technology, like SpeedyLight+ from PRT, has given installers a simpler, faster and more reliable method for curing than ever before. Schedule a demo to learn more: